Our Quality Assurance Mission

We work hand-in-hand with each customer to identify critical characteristics to help us develop and customize a quality control plan for each plastic mold or plastic injection molding product. This quality control plan is consistently followed and documented during every production step of your product order.

Precision Quality Assurance

We understand the importance of meeting tight tolerance or others requirement for our customers. Our creative approach to streamlined manufacturing and problem solving allows us to provide high quality complex moulds. Our quality control system is based on the principles of ISO9001:2015 that guide our daily tasks and quality inspection on-site. Every new project at PPS Industrial begins with our quality inspection program review process to ensure we understand your product quality needs from the beginning.

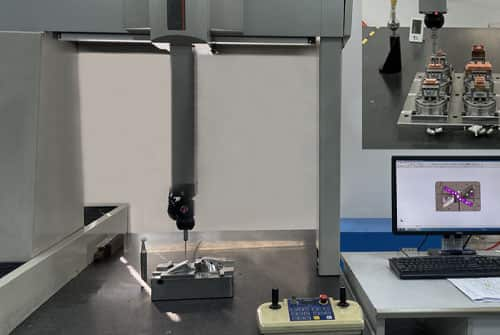

CMM On-site Inspection Control

√ Electrodes measuring

√ Cavity steel checking

√ Cavity hardness checking

√ Workpiece measuring by process

√ Pre-Assembly checking

√ Mould function checking by testing

√ Mould physical checking

√ Shipment checking

Quality Systems

√ Self auditing

√ Capability studies and gage studies

√ Job specific work instructions to ensure consistency

√ Team Program Review

Sample Dimension Measurement Control

The precision instruments utilized by the quality department include:

√ Calipers | Part Specific fixtures

√ Gauge pins and Micrometers

√ CMM is programmed with parameters for inspection consistency

√ two-dimensional image measuring instrument

Quality Reports Control

√ Electrodes Inspection Report

√ Standard Component Check Report

√ Steel Inspection Report

√ T1/T2/T3 Trial Report

√ Sample Measurement Report

√ CPK Check Report(Capability process index)

√ PPAP Report (we can provide this report if the customer require to submit)

Other Inspection tools

|

|

Raw Material Inspection

The company has established a rigorous inspection process for raw materials, flexibly using GB2828 sampling inspection, and implementing full inspection for some core materials for quality control.

|

|

| Material hardness test | Mechanical test |