2D & 3D part files and mold specifications are preferred. We mainly use UG and AUTOCAD. But it is OK for us to read the files of Solidworks, PRO-E, etc.

No Minimum MOQ

No Minimum MOQ

In-house Production

In-house Production

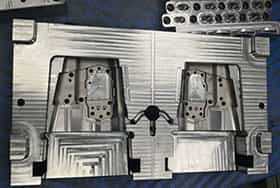

State-of-the-art Manufacturing Facilities.

All Production and Quality-Control In-House.

Quick & Precision

Quick & Precision

Turn Around As Fast As 1 day. Tight Tolerance Up To 0.005mm.

CMM Reports & Steel Certificate Will Follow Parts.

7*24*365 Service

7*24*365 Service

Instant Customer Service. Strict Expert Quality Control System.

Mold Components Machining Features

It is nessary to make an insert for where areas cann't be machined by CNC,EDM or add ventilation.

It is nessary to make an insert for where areas cann't be machined by CNC,EDM or add ventilation.

When there is weak steel, it will be added an insert for changing a new one in the future.

When there is weak steel, it will be added an insert for changing a new one in the future.

It is essential to make an insert for interchanging to get different part shape or changing to get tight torlerance,

It is essential to make an insert for interchanging to get different part shape or changing to get tight torlerance,

It is essential to make an insert for polish where some areas of cavity side or core side are too deep or small.

It is essential to make an insert for polish where some areas of cavity side or core side are too deep or small.

Flexible MOQ Flexible MOQ |

Turn Around As fast As 3 Day Turn Around As fast As 3 Day |

|

(Like 1.2343 1.2711 1.2738 H13 420 P20 And More.) |

|

|

|

|

|

| Core Insert | Mould Slider | Precision Injection Mould Insert | Precision Injection Mould Insert |

|

|

|

|

| Runner inserts | Slider Inserts | Slider For Automotive Mould | Slider For Electronic Product Mould |

|

|

|

|

| Inserts For Automotive Mould | Inserts For Aumotive Mould | Inserts For Home Appliance Mould | Inserts For Home Appliance Mould |

How To Work With Us

|

|

|

|

Step1:Provide Design Drawings Including 2D+3D Drawings, Materials quantities, and relevant important information

|

Step2:Production & QC Transformation from drawing file to part

|

Step3:Received Goods We deliver high-quality parts directly to you.

|

Mold Manufacturing Blogs

2D & 3D part files and mold specifications are preferred. We mainly use UG and AUTOCAD. But it is OK for us to read the files of Solidworks, PRO-E, etc.

Yes, we do. over 96% of our plastic moulded products are exported.

110, We have day shift and night shift.

25-30 sets. max can be 30~40sets

Max 24 ton. The mold size is Max 3.5 m x 2.5m x1.5m.

Yes. And we can hold mould tolerance +/- 0.01mm, product tolerance +/- 0.02mm.