| Part requirement description: |

| 1.Part with undercuts picking up by robot |

| 2.Mismatch within 0.01mm |

| 3.Part without filling marks |

| Challenge: |

| 1.4 sliders without mismatch. |

| 2.Vale gate on part surface without any mark. |

| 3.Inside undercuts around parts demolding by force release without deformation. |

| 4.Inside undercut with proof wate function do not accept air trap or short shot. |

| Solution: |

| 1.1-1.All sliders machining by High-Speed CNC. |

| 1-2.Mirror EDM to ensure high precision. |

| 1-3.Assemble 4 sliders together to adjust mismatch by polishing. |

| 1-4.Trial mold to check the mismatch ,and then graining. |

| 2.2-1.Add individual cooling line for hot nozzles . |

| 2-2.Improve flow marks by adjusting mold temperature and injection speed. |

| 3.3-1.Improve parting line to decrease sticking on core side risk. |

| 3-2.Add Teflon on core side. |

| 4.4-1.Make MF in advance to check air trap area ,then reserve insert space. |

| 4-2.After run T1 to check detail air trap areas, make inserts for venting |

| Benefits: |

| PPS Industral was able to make this mould at the best solution ,a competitive price,and at a higher quality than the incumbent OEM. |

| Saved Customer money by identifying,clarifying,and resolving issues early in mould design process. |

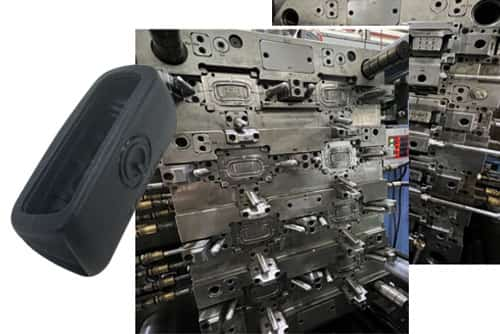

Precision Injection Mold Specification:

| Part number | PIU320176 |

| Raw Material | TPE |

| Wall thickness | 1.5mm |

| Part cavity | 1*8 |

| Part surface | cavity side:600(Texture),core side:400 |

| No. of Actions | 16 sliders |

| Injection system | valve pine on the parts |

| Ejection Type | machinary |

| Standard Parts | HASCO |

| Mold steel | cavity insert:1.2344,core insert:1.2344 |

| Moldbase steel | A,B plate:1.2312 others:1.1730 |

| Mold size | 850*750mm |

| Tooling Life(shots) | 100万 |

| Leadtime | 7weeks |

| Press machine | 380T(Haitian) |

| Cycle time | 45s |

| Exporting country | France |