The injection mold cooling system purpose is to ensure uniform cooling of the molded product and then eject the product out within a short period of time. The layout of the cooling channel plays an important role in the injection molding quality as well as the production cycle (cost) of a product.

Influence on Quality: During the injection molding process, the cooling channel is used to control mold temperature, of which the fluctuation has a direct influence on product shrinkage, deformation, dimensional stability, mechanical strength, residue cracks and surface quality, etc. Mainly include: surface glossiness, residue stress, crystallinity and thermal flexure.

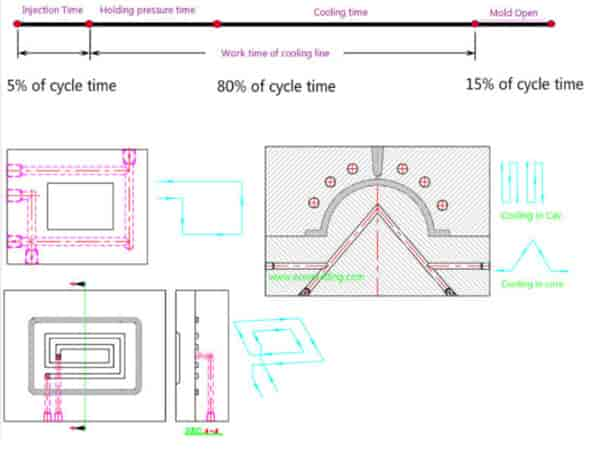

Influence on Production Cycle: An injection molding cycle is mainly composed of the following steps. Reducing the cooling time means an improvement in the injection molding efficiency.

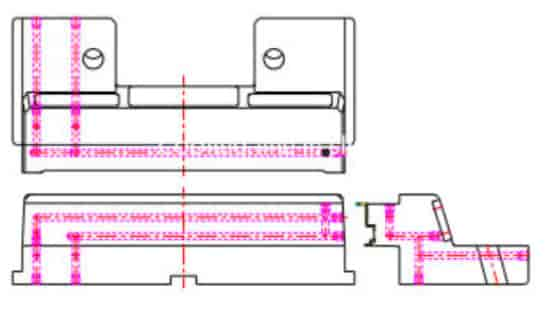

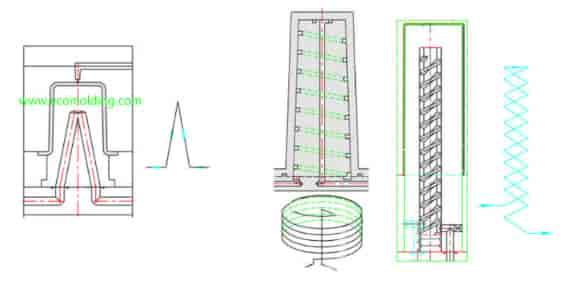

1,Cooling line in core /cavity inserts

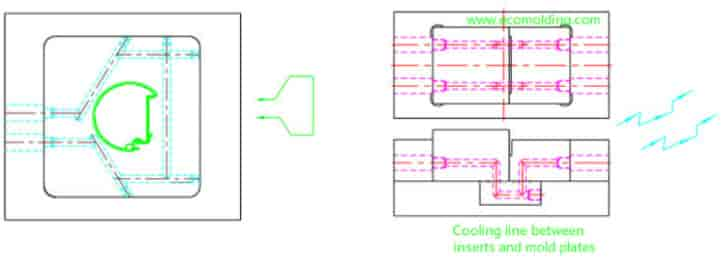

2,Connecting cooling line between mold plates and inserts

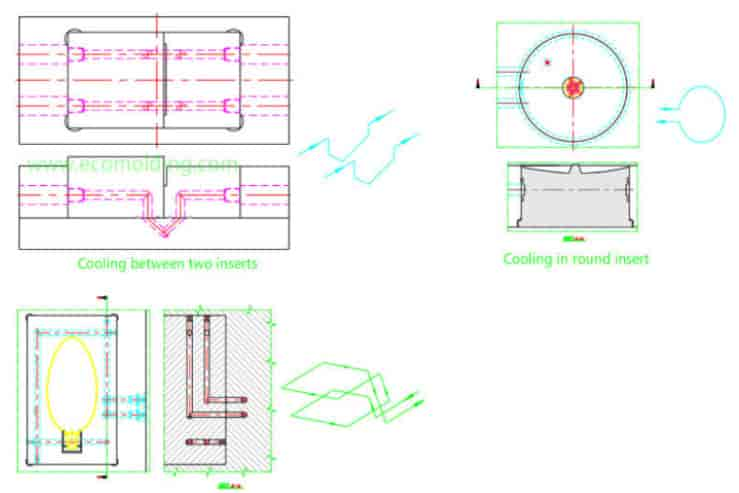

3,Different cooling line type

4,Cooling tower

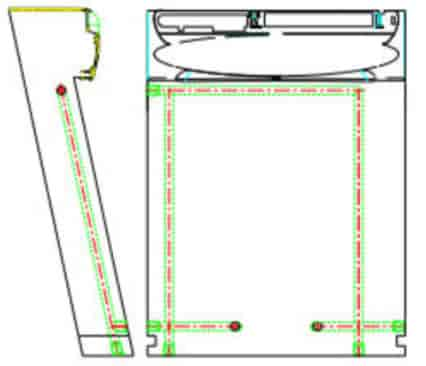

5,Cooling line in lifter

6,Cooling line in slider